Company Profile.

Led by a technocrat having more than 30 years of experience in the field, Kalpatech was established in 2005. With over 15 years of continual research, development and improvement, Kalpatech is now a recognized name in flat and profile wire. Over the years, we have started manufacturing of wide range of profiles with precise control on dimensions to meet the customers' requirements and uses of different shapes in applications like Filtration in petrochemical, oil, water, pulp and food industries, mining industries, architecture, home appliances, building industries, textile machineries, automobile industries and general purpose.

Our standard profile range from 2.00 mm2 to 35 mm2 of cross section with a maximum width of 15.00 mm. The shapes are produced on a state of the art Universal Cold Rolling Mill with following highlights:

- Continuous dimensional checks with CONTACT type measuring system during rolling for highest accuracy.

- Close dimensional controls up to +/-0.030 mm in width and +/-0.010 mm in thickness.

- Dimensional checks of the finishes shaped wires are done on Auto Focus Vision Measurement System.

Following are some of the salient features of the products manufactured by us successfully.

| Sr. No. | Description | Image | Size Range (Width x Thickness) | Tolerance (Width x Thickness) | Surface Finish | Application |

|---|---|---|---|---|---|---|

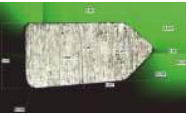

| 1 | Bullet Shape Wire |  |

7.60mm x 3.65mm | (+/-0.03mm) x (+/-0.03mm) | Bright only | For Separation technology in Petrochemical Industries, in Food Industries for Separating pulp & Juices |

| 2 | Hi-Flow Bar Wire |  |

7.50mm x 3.50mm | (+/-0.03mm) x (+/-0.03mm) | Bright only | For Separation technology in Paper Industries. |

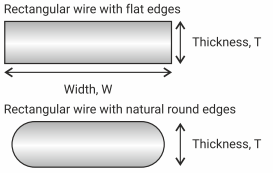

| 3 | Flat Wire/Rectangular Wire |  |

1mm to 14mm (Width) x 0.4mm to 4mm (Thickness) | (+/-0.03mm) x (+/-0.01mm) | Bright or Matte | In spring companies for manufacturing helical, conical, torsion, compression and other special purpose springs. In automobile companies for manufacturing of piston rings, Vertebra used in windshield wipers. In manufacturing of fasteners and washers. In kitchenware and basket industry. |

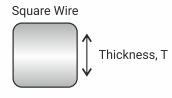

| 4 | Square Wire |  |

1mm to 4mm (Side) | (+/-0.03mm) | Bright or matte | For manufacturing piston rings. For manufacturing of spring washers. In spring companies for manufacturing helical, conical, torsion, compression and other special purpose springs |

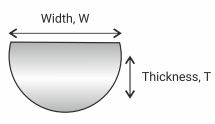

| 5 | Half Round Wire |  |

1mm to 6mm (Width) x 0.4mm to 3mm (Thickness) | (+/-0.03mm) x (+/-0.01mm) | Bright or Matte | Used in wire meshes. Used for manufacturing cotter pins/split pins |

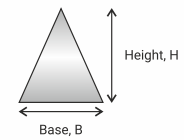

| 6 | Triangular Wire |  |

1mm to 8mm (Height) x 0.4mm to 4mm (Base) | (+/-0.03mm) x (+/-0.01mm) | Bright only | Used in the manufacturing of flat screen & sieve for oil mill, sugar, corn processing, food processing. Used in manufacturing of filters which are put into service in mining, mineral processes etc. |

| 7 | Other Custom Shapes |  |

1mm to 7mm (Width) x 0.4mm to 4mm (Thickness) | (+/-0.03mm) x (+/-0.01mm) | Bright only | Used in the manufacturing of flat screen & sieve for oil mill, sugar, corn processing, food processing. Used in manufacturing of filters which are put into service in mining, mineral processes etc. |

| Grade Availability & Condition: | All flat/Shape wires are available in every grade of any ferrous and non-ferrous alloy. Moreover, the wires are available in all temper conditions i.e. Soft annealed, 4 hard, 1⁄2 hard, 4 hard, full hard. | |||||

|

Packaging: |

|

|

||||

| 8 | Flattening/Shaping Roller Assembly | Outer Diameter: 100mm to 300mm In Length: 200mm to 1000mm |

As per customer drawing | Ground & lapped to mirror finish (with under 0.001mm runout) | Used for wire flattening/shaping |

Our Mission & Vision

Mission

Our mission is to Design & manufacture the rolling mills with high precision & Invention to full fill the quality, productivity & Safety need of our customer.

The company is dedicated to supplying high-quality flat and shaped wires, emphasizing continuous improvement and active employee involvement. Through these efforts, Kalpatech ensures excellence in its products and services, setting industry standards and exceeding customer expectations.

Vision

To Become a global supplier for rolling mills, Continuous casting machines, non-ferrous flat & shaped wires by achieving world class practices

The company aims to achieve this vision through world-class practices, setting industry standards, and prioritizing customer satisfaction, thereby establishing itself as a preferred choice in the global market.

Our Core Values...

Integrity.

At Kalpatech, integrity is paramount. The company adheres to the highest ethical principles and standards. Every action taken by the team is rooted in the concept of doing the right thing at the right time and for the right reasons. This unwavering commitment to integrity ensures that every decision made is honest, fair, and just.

Respect

Respecting the inherent value and uniqueness of every individual is a core principle at Kalpatech. The company values the diverse perspectives and backgrounds of its employees, clients, and partners. Treating everyone with dignity and courtesy forms the basis of respectful interactions within the organization and with external stakeholders.

Customer Value.

Understanding and fulfilling customer needs is at the heart of Kalpatech's mission. The company takes pride in comprehensively understanding the requirements of its customers. Beyond mere understanding, Kalpatech is dedicated to delivering on its promises. Customer satisfaction is not just a goal but a commitment, ensuring that clients receive the quality and service they expect.

Accountability

Kalpatech believes in accountability as a demonstration of courage and honesty. Taking responsibility for one's actions is not just a requirement but a virtue within the company. Team members are encouraged to be accountable for their decisions and actions, fostering an environment of trust and responsibility.

Innovation

Embracing innovation is part of Kalpatech's DNA. The company actively seeks and invests in opportunities by leveraging its knowledge and experience. Innovation is not just a buzzword; it is a practical approach that allows Kalpatech to stay ahead in a rapidly changing world. By embracing new ideas and technologies, the company continues to evolve and meet the ever-changing needs of its clients.

Why? Kalpatech

- Our approach to customer’s requirement is what makes us different from others.

- Extensive range of products.

- We strive to deliver goods with equal devotion.

- we are a regular supplies to various clients across industries.

- Our aim is to have long-term customers by offering customer satisfaction along with customer delight .

Our

Clients